How to Ruin Your Lean Six Sigma Projects?

During my training sessions and coaching assignments, I often get asked the following question: “What do I have to do to avoid the failure of my Lean Six Sigma (LSS) project?” It is a smart and logical question that will always pop up in the mind of a six sigma practitioner. Now that team members have concluded the training and learned all the tricks and tools to start a project; they are eager to kick-start the project and start demonstrating the powerful methodology. And, more than anything else, they need to succeed! Below are my suggestions based on my personal experience and supported by literature published in this field.

Six Sigma is a powerful methodology that combines the uniqueness of project execution, teamwork, data and problem analysis, structured approach, and a mix of quantitive, qualitative and financial accountability.

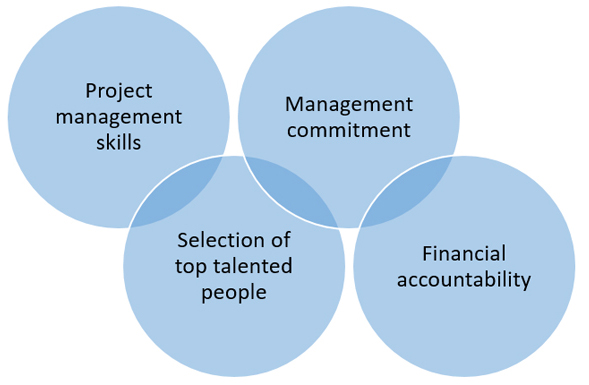

There has been growing discussions and research focusing on LSS critical success factors (Coronado et al. 2002; Kumar 2007; Anwar et al. 2015; Albliwi & Antony 2014). Many researchers argue that the factors listed in the box below are critical to the success of LSS projects. These results have been deduced from empirical research and have been published in many reputable journals.

|

Cultural change

Leadership style Management commitment LSS training Organization infrastructure Communication Linking LSS to business strategy Linking LSS to customer Linking LSS to HR rewards Extending LSS to supply chain |

LSS projects prioritization

LSS projects tracking and review Project management skills Tools and techniques LSS financial accountability Data-based approach Communication and awareness Selection of staff for LSS Resources to LSS team |

Figure 1: Factors showing the primary four spheres of concern from a recent paper published by Anthony and Laureani (2016)

The areas in figure 1 are expanded and discussed below where I address six barriers that could either hinder project initiation or lead to failure at a later phase of the SS project. The research findings are in line with my observations based on my hands-on experience coaching over 250 projects in areas of quality, lean and six sigma.

Project management skills failure related factors:

- Lack of project alignment with business strategy and objectives. The selection process may be flawed and may have ended up selecting ‘pet’ projects or projects that are department focused. At a later stage, disorientation and lack of interest may result in abandoning these projects. An excellent tool to use at the selection stage is the weighted matrix. This will lead to selecting projects that have higher rates of success. I would suggest scoring the following criteria: voice of customer, voice of business, financial return, risk, ease of implementation and availability of data. Brainstorming or Delphi are excellent tools to use at this stage.

- The project scope is too broad. “Do not try to boil the ocean!” It is critical to zoom into a particular problem area at the project initiation stage. Lean Six Sigma is a project, and every project has time and cost constraints which you may have agreed to with your sponsor and stakeholders. These constraints have to be honored. You have to select a scope that is feasible and achievable within the time frame and resources provided. Writing a well-formulated problem statement at this stage can help narrow the focus and ensure proper and viable project execution.

Leadership and Top management support failure related factors:

- No commitment from the leadership. The lack of this element is considered the biggest challenge for an LSS project. LSS projects deployment is a top-bottom approach, and without the appropriate management support your project is doomed to fail. Therefore, make sure that the leadership is aware of the project scope, details, and resources needed before jumping into an LSS project. Seek to secure the support of organization champions that believe in the value of the LSS and are ready to ‘fight’ with other departments to obtain process approvals or access to data.

- Poor communication: 90% of the time during the project is spent on communication. Excellent communication enables LSS teams to work more efficiently to achieve their results; good communication is essential to developing other critical business and life skills. Being able to communicate well with others is often the key to solving problems and decision making. LSS practitioners need to be excellent oral and written communicators to excel in the many roles they will play: trainers, coaches, and mentors. They should be able to speak intelligibly to all types of audiences, explain the project’s benefits and scope, and update stakeholders on progress. Lack of these skills can affect the project’s success and delay its progress. Furthermore, regularly updating and reporting in writing are critical requirements to ensure the success of LSS projects.

Selection of top talented staff failure related factors:

- It takes a collection of unique characteristics for the LSS practitioner to make a project succeed. Among these characteristics are the ‘can do attitude’, change management skills, communication skills, problem-solving skills, technical expertise, team skills and customer advocacy. Care should be taken to select team members that exhibit many of these skills. Needless to say that many teams will fail because of the lack of these critical skills.

Financial accountability failure related factors:

- LSS projects performance and achievement must be linked to the financial performance of the organization. The project will suffer if there is no clear financial return for the project. From the outset of the project, there must be clear expected financial gains. At the end of the project, these expectations are confirmed and documented during the control stage and project closure.

In addition to the above factors, the following factors may present challenges to the success of LSS: lack of data-based approach, No linkage to HR rewards, and poor project tracking and review

In conclusion, make sure you have the above factors in place before you start your Lean six sigma project. It is often said that failing to prepare is preparing to fail; so spend enough time making sure the above ingredients are available and discussed before jumping into your next LSS project.

References:

Albliwi, S. & Antony, J., 2014. Critical failure factors of Lean Six Sigma: a systematic literature review. International Journal of Quality & Reliability Management Vol., 31(9), pp.1012–1030.

Anwar, F. et al., 2015. Critical success factors of Lean Six Sigma deployment: a current review. International Journal of Lean Six Sigma, 6(4), pp.339–348.

Coronado, R.R.B. et al., 2002. Critical success factors for the successful implementation of six sigma projects in organizations. The TQM Magazine, 14(2), pp.92–99.

Kumar, M., 2007. Critical success factors and hurdles to Six Sigma implementation: the case of a UK manufacturing SME. International Journal of Six Sigma and Competitive Advantage, 3(4), pp.333–351.

Laureani, A. & Antony, J., 2016. Leadership – a critical success factor for the effective implementation of Lean Six Sigma. Total Quality Management & Business Excellence, pp.1–22.

Related Articles

Implementing Lean Six Sigma In Healthcare: Benefits, Facts, And 7 Tips For Success

As a Black Belt Lean Six Sigma practitioner, I enjoyed leading and executing…

Should organizations allow customers to complain?

In this globalized world competition is fierce at all levels. Segments…

Six Sigma as a Vehicle to Reduce Cost of Poor Quality (COPQ)

Six Sigma emerged as a problem-solving methodology in an effort to…

Six Sigma and EFQM Comparison, Similarities and Differences: A critical analysis by a practitioner

Which is better to use in an organization? Should I use Six Sigma or EFQM…