PART 3: Supply Chains are Suffering from Long COVID. This is what they’ll recover to look like

The attending physician exits the ER and walks straight toward the patient’s family. She doesn’t mince her words, “Mr. Shmoe is lucky to have escaped with his life. However, unless he makes lifestyle changes, there are no guarantees next time around.”

Supply chains, too, have escaped with their lives, having contracted Long COVID, as detailed in Part 1 of this series. In Part 2, I prescribed a vaccine to improve robustness against disruption. But like Mr. Shmoe, medical care will not suffice—proverbial lifestyle changes are in order. Supply chains must adapt to a wave of growing trends to excel in an increasingly dynamic world. In today’s third and final part of the series, I address four such trends and provide a vision for how each is gearing up to manifest itself by 2030.

Trend 1: Local sourcing.

Manifestation: In 2030, a modern supply chain is where sustainably harvested raw materials travel no more than 100km from source to consumer. This shift has multiple drivers, with economic, environmental, and social bottom lines all set to benefit.

Economically, there are cost savings to be made by sourcing closer to home as shipping distances are slashed, and the need for carrying large stocks is reduced. Also, sourcing risks rooted in geopolitics are hedged as there is less reliance on trading partners outside a company’s jurisdiction. (Examples of such risks range from trade wars and natural disasters to lockdowns and shipping constraints.)

With governments coming under increasing pressure to act against environmental goals, additional savings are needed on carbon emissions associated with long shipping voyages. The global shipping industry is responsible for close to 1 billion tonnes of CO2 emissions every year. To put in perspective, this represents close to 3% of global CO2 emissions. Moving toward local sourcing can help cut that figure considerably.

Finally, buying locally will affect the community as local suppliers thrive, creating jobs and boosting disposable income.

One company that has successfully moved toward sourcing from within a 100km radius is, well… “100km Foods”. Based in Toronto, this wholesale food distributor aims to connect chefs with products from local farmers and producers. It’s a win-win as farmers gain access to extensive local markets and chefs secure a regular supply stream of fresh ingredients.

Trend 2: Drones for last-mile delivery.

Manifestation: Look outside your window in 2030, and you are forgiven for mistaking your local neighborhood for the planet of Naboo (as seen in Star Wars: Revenge of the Sith). The reason? A drone-dotted sky. Technologically, we are already there, and drones are too good to be swept under the rug. It is only a matter of time before government regulation catches up. For supply chains, the most wins are set to be made in delivering the last mile, replacing motorbikes, and what have you, with drones for that stretch of road from the kitchen to consumer.

The drivers for this trend are again plenty. Consider a delivery bike travels 3,000km a day. The operating costs for running such an itinerary (excluding driver salaries) for a fleet of 1,000 bikes can run up to $350 thousand a month. Associated carbon emissions range between 15 and 20 thousand tons. Migrating to drone technology reduces both (financial and environmental) costs to the point that they are relatively negligible.

Finally, the increasing pressure on demand for home delivery since the COVID outbreak has increased the number of traffic accidents associated with last-mile deliveries by as much as 25%. With drones, the risk to drivers drops to practically zero.

Supply chains will find that replacing bikes with drones can improve delivery productivity, reduce costs, benefit the environment, and save lives. Employers and educators have the responsibility to reskill drivers and provide them with opportunities to thrive—a challenge mankind has consistently excelled at with every technological breakthrough since oxen replaced plowing farmers 7,000 years ago.

Trend 3: Robotics in manufacturing.

Manifestation: In 2030, the classification of a product as “artisanal” has evolved to include “products built by a human-apprenticed robot.” Like drones, robots in a factory work non-stop, perfectly replicate every move, and are indifferent to labor unions. The best part? They operate in the dark, saving on lighting.

When Tesla moved into its Fremont Factory, the company invested in the most sophisticated robotic systems it could source. Still, those assets were useless without training. The company hired specialized talent to program the robots for manufacturing tasks. One such task involved welding, a sensitive and tedious job. The company brought in master-welder Brad Johnson and had him spend 18 months training a robot. In the long run, those training investments were offset by the low cost of operating the robots and the ability to increase the acquired skills across many robots.

Even small businesses are set to benefit from robotics in the future as more industries migrate manufacturing to cloud manufacturers (while retaining control of branding and marketing). These mega manufacturing centers can invest in robotics and pass on the benefits to their partners.

Trend 4: Blockchain for tracking.

Manifestation: A surprising percentage of delivery delays is due to problems with shipping documents. In 2030, blockchain applications in commerce will eradicate issues with documentation and the need for documents.

Snafus, such as the Invoice not matching the Purchase Order, receiving a ship before the Bill of Lading, and banks taking their time to amend a Letter of Credit, are nipped in the bud. A single digital ledger replaces every shipping document, including the Purchase Order, Invoice, Packing List, Bill of Lading, Certificate of Origin, Quality Certificate, and Letter of Credit. More importantly, the transaction is error-free, fool-proof, and less prone to fraud. It also provides real-time updates and tracking on shipping transactions to all parties involved, including buyers, sellers, shippers, customs agents, and banks.

Further, Advanced Analytics leverage data from blockchain to benefit shipping deliveries, improve timeliness, and reduce cost.

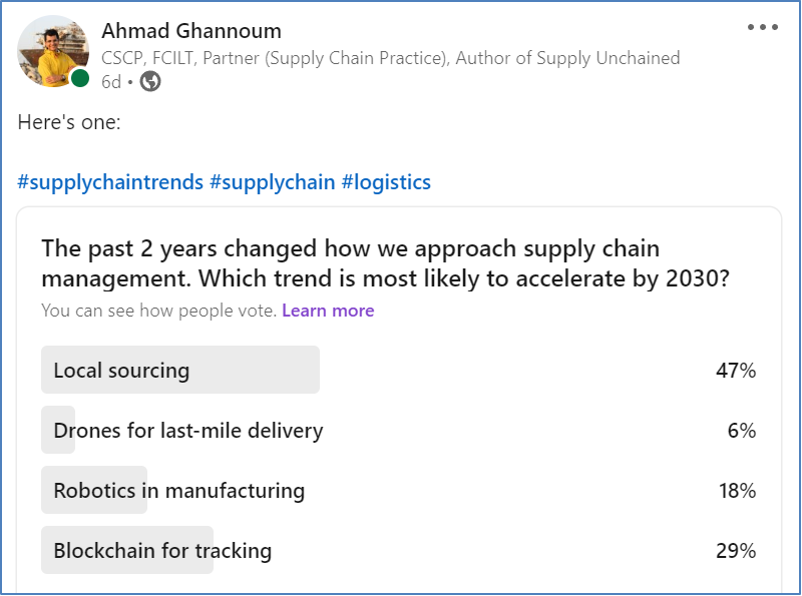

Of the four trends highlighted above, which is more likely to accelerate by 2030? I posed the question to my LinkedIn network; 47% of respondents singled out local sourcing as the most likely trend in supply chains. On the other hand, drones garnered the lowest score with just 6% of the vote (see screenshot at the bottom). Oh, and one more thing: spare a thought for Mr. Shmoe. In 2030, he continues to persevere on that treadmill.

Related Articles

PART 2: Supply Chains are Suffering from Long COVID. Here’s the Vaccine

Global supply chains are still suffering from Long COVID two years after…

Supply Chains Are Suffering from “Long COVID”. Here’s Why and What to Expect Next

Two years after the onset of the COVID-19 pandemic, the world still reels…

Business in the Time of COVID-19

The cat is out of the bag. One way or another, the novel coronavirus outbreak…

No Cheese, Please! Balancing Flexibility and Efficiency in Supply Chains

Don’t get me wrong, I love Thai food. But having spent the best part of…