Achieving Patient Excellence through Lean Six Sigma in Healthcare

Introduction

Why do hospitals need lean principles or methodologies? We all come to work to do our very best - to achieve what we are capable of and to add real value for our patients and ensure clinical expertise is supported by process excellence to enable processes to flow at the rate of patient demand. Healthcare caregiver teams are dedicated and skilled professionals who are often under pressure to do their best and work terrifically hard - but often the processes are inadequate. Each year, the National Patient Safety Agency handles over one million reported medical incidents in England alone. Figures illustrate that approximately one in every ten patients are unintentionally harmed by their healthcare providers. Most of these are not necessarily the result of medical errors or poor clinical decisions, but are caused simply by the way the system has been set up. Hospital caregivers (employees) are often frustrated with the recurring problems they face every day, as many go home exhausted or end up leaving their profession. Hospitals do many wonderful things, but an administrator at a prestigious university hospital lamented that "we have world-class doctors, world-class treatment, but completely broken processes." How can an approach called Lean be of help to hospitals? Upon hearing the word, people might complain that they are already understaffed (what they think lean means, in everyday language) and already work as hard as they can. Rest assured, the approach presented here is not about mass layoffs or caregivers doing more. The idea of "preventable" errors may bring skepticism, as caregivers believe they are already being as careful as possible, Hospitals using Lean methods do not improve quality by asking people to be more careful any more than they improve productivity by asking people to run around faster. Lean is a toolset, a management system, and a philosophy that can change the way hospitals are organized and managed. Lean is a methodology that allows hospitals to improve the quality of care for patients by reducing errors and waiting times.

Lean Methods Are Not New to Healthcare

Frank and Lillian Gilbreth, sometimes known by the original version of the cheaper by the dozen movie were two of the Original efficiency experts of the late nineteenth and early twentieth centuries, with many of their methods influencing the later development of Lean. Outside of their primary factory work, the Gilbreths published many studies in medicine, being among the first to demonstrate that industrial engineering methods could be applied to hospitals. One innovation from the Gilbreth studies was having a surgical nurse hand instruments to surgeons as called for, instead of the surgeon taking time away from the patient to retrieve them, a better practice we take for granted today.. Henry Ford in 1922,wrote about efforts to apply his production methods to a hospital in Dearborn, Michigan. Ford said, "It is not at all certain whether hospitals as they are now managed exist for patients or for doctors.... It has been an aim of our hospital to cut away from all of these practices and to put the interest of the patient first.... In the ordinary hospital the nurses must make useless steps. More of their time is spent in walking than in caring for the patient. This hospital is designed to save steps. Each floor is complete in itself, and just as in the factories we have tried to eliminate the necessity for waste motion, so we have tried to eliminate waste motion in the hospital.'? Ford uses the word waste, which has a similar context and meaning in the Lean terminology, to mean any motion or effort that does not provide any value for the customer (or patient). Lean is an approach that can support employees and physicians, eliminating roadblocks and allowing them to focus on providing care. Lean is a system for strengthening hospital organizations for the long term, reducing costs and risks while also facilitating growth and expansion. Lean helps break down barriers between disconnected departmental "silos," allowing different hospital departments to better work together for the benefit of patients. Someone might ask how Lean methods can help solve the everyday, nagging problems that so many committees and teams have already tried fixing. Lean is different in that the methodology shows people how to look at the details of processes, fixing things where the work is actually done, by the people who do the work, rather than relying on experts to tell them exactly what to do. Lean helps leaders see and understand that it is not the individuals who are broken, but the system itself. This happens in a way in which the system can actually be fixed and improved in small, manageable bites. The Lean approach also requires the continued learning and professional development of employees, for their own sake and the organization and system's sake…

Lean Is Helping Hospitals Improve

It is difficult to pinpoint exactly when hospitals started looking, once again, outside of their industry for Lean ideas. Some hospitals started experimenting with Lean methods in the 1990s, in some cases with help from Michigan automakers. In 2001, a study was conducted by the Robert Wood Johnson Foundation that looked across hospitals for leaders who did things dramatically differently than in other hospitals. Foundation executive vice president Lewis Sandy said, "We want to see a Toyota in healthcare. That's been one of the barriers in healthcare .No one can point to a health system and say 'That's how it ought to be done.. The motivation was clear that hospitals had to look beyond their peers to find solutions to widespread systemic problems. There are now many examples of the positive impact Lean is having in hospitals throughout the world. As a sample, Lean methods have resulted in: ü Reduced turnaround time for clinical laboratory results by 60% without adding head count or new instrumentation - Alegent Health, Nebraska. ü Reduced instrument decontamination and sterilization cycle time by over 70% - Kingston General Hospital, Ontario. ü Reduced patient deaths related to central-line-associated blood stream infections by 95% - Allegbeny Hospital, Pennsylvania. ü Reduced patient waiting time for orthopedic surgery from 14 weeks to 31 hours (from first call to surgery) - ThedaCare, Wisconsin. ü Increased surgical revenue by $2,808,000 annually - Ohio Health, Ohio. ü Reduced patient length of stay by 29% and avoided $1.25million in new emergency department construction - Avera McKennan, South Dakota. ü Saved $7.5 million from Lean Rapid Improvement Events in 2004 and reinvested the savings in patient care - Park Nicollet Health Services, Minnesota. “Source – AHA; 2013 Sample study about lean principle adoption across US hospitals”.

Lean Six Sigma – an Overview

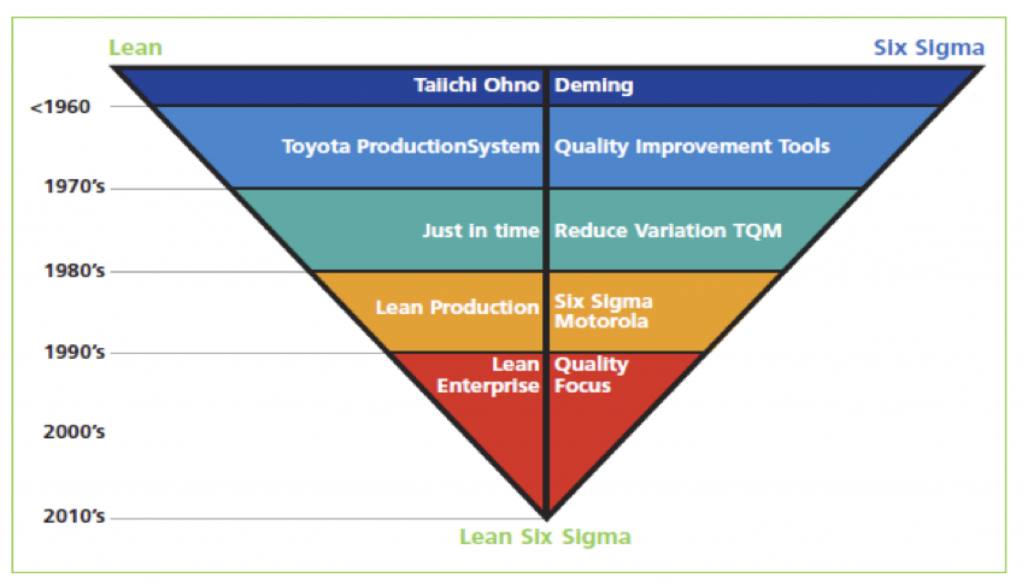

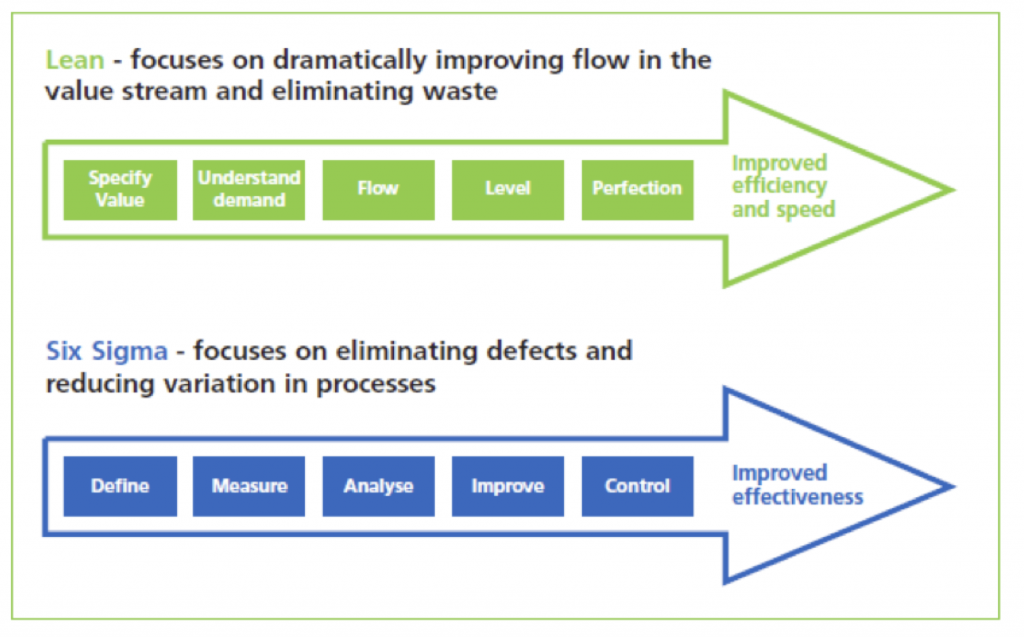

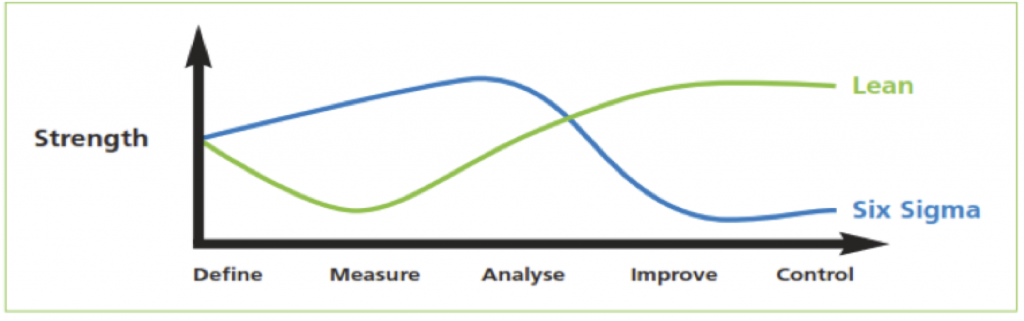

Lean is an approach that seeks to improve flow in the value stream and eliminate waste. It is about doing things quickly. Six Sigma uses a powerful framework (DMAIC) and statistical tools to uncover root causes to understand and reduce variation. It is about doing things right (defect free). A combination of both provides an over-arching improvement philosophy that incorporates powerful data-driven tools to solve problems and create rapid transformational improvement at lower cost. The key is to find the optimal combination of both approaches. For example, adopting the Lean idea of focusing on what adds value and then using Six Sigma tools to help understand and reduce variation, when the value stream is agreed. This figure below shows the roots of Lean and Six Sigma and how they are converging.

Globally, organizations from many industries, including healthcare are adopting a ‘Lean Six Sigma’ strategy. This is particularly true of organizations that previously focused on Six Sigma. General Electric, one of the pioneers of Six Sigma, is now incorporating a Lean Six Sigma approach to achieving rapid transformational change at lower cost.

Introduction to Lean

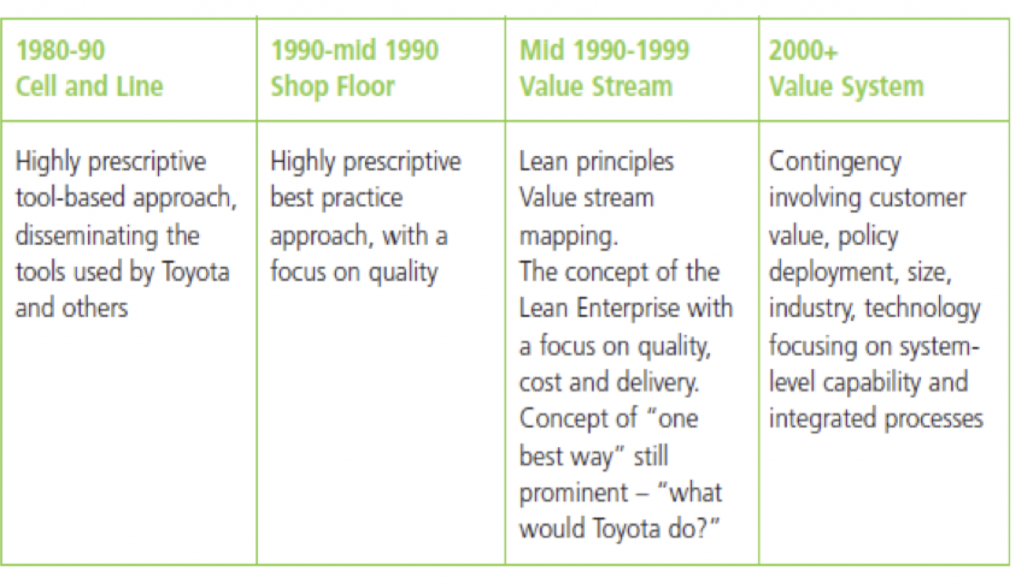

Lean principles have been enhanced and developed by Toyota to create the Toyota Production System (TPS). Toyota developed Lean in the 1950s based on the work of Frederick Taylor and W. Edwards Deming, both industrial engineers. (Note, Toyota does not refer to the word Lean, it uses the Toyota Production System. See Table 1.) Stephen Spear’s paper in Harvard Business Review (2005) says, “If one asks the question, can the Toyota Production System be applied in healthcare? The quick answer is Yes.” Industrial engineers invented both Lean techniques and the Six Sigma approach to process quality.

Table 1 – Evolution of the Lean Approach

Lean is a strategic approach to change and improvement. Focusing just on the tools at an operational level and reducing costs, will not obtain the full benefits. Lean means, “using less to do more” by “determining the value of any given process by distinguishing value added steps from non-value added and eliminating waste so that ultimately every step adds value to the process”. It is relentlessly focused on the work and by definition, the strategy becomes:

- Focus on the work, Learn from it and Improve. That is your strategy. The strategy is simply to learn.

- Not understanding Lean and applying tools in isolation leads it to be a cost-reduction exercise.

- The main criticisms of Lean are summarized as:

- Lack of consideration for human factors.

- Lack of strategic perspective (at least until recently).

- Relative inability to cope with variability.

- Lean means laying off people.

- Lean is only for manufacturing.

- Lean only works in certain environments – but it is more than manufacturing process design (a strategic approach).

Introduction to Six Sigma

Six Sigma is a process improvement methodology developed at Motorola in the 1980’s to reduce defects in its processes. Its goal was to achieve a level of performance equal to a defect rate of 3.4 defects per million opportunities – this is a virtually defect free environment i.e. Six Sigma performance. Similarly, Motorola Inc. Six Sigma methodology emerged in the 1980s from Total Quality Management (TQM), a core element of industrial engineering. Six Sigma as a measurement standard in product variation can be traced back to the 1920's when “Walter Shewhart” showed that three sigma from the mean is the point where a process requires correction. Many measurement standards later came on the scene, but credit for coining the term "Six Sigma" goes to a Motorola engineer named Bill Smith. The main criticisms of Six Sigma are summarized as:

- system interaction not considered – uncoordinated projects

- processes improved independently

- lack of consideration for human factors

- significant infrastructure investment required

- over detailed and complicated for some tasks

- it is the new flavor of the month

- the goal of Six Sigma (3.4 defects per million opportunities) is absolute – but this is not always an appropriate goal and does not need to be adhered to rigorously

- it is only about quality.

Lean and Six Sigma are process based improvement methodologies. Both were developed in manufacturing environments. Both have proven their effectiveness. Proponents of both can point to numerous, and dramatic success stories. Current emerging trends are indicating that integrating the best elements of both methodologies could help healthcare deliver strategic and operational objectives.

What are the advantages of integrating Lean and Six Sigma?

Integrating Lean and Six Sigma creates a win-win situation. The philosophy of Lean provides the strategy and creates the environment for improving flow and eliminating waste. Empowered staff are encouraged to continuously improve to create value adding opportunities that otherwise would not be identified. Six Sigma helps to quantify problems, makes evidence based decisions (this prevents wasting time on anecdotal evidence), helps to understand and reduce variation and identifies root causes of variation to find sustainable solutions. Furthermore, it quantifies the financial benefits and savings. This helps to focus efforts in the areas that offer the most potential for improvement. A combination of both can provide the philosophy and the effective tools to solve problems and create rapid transformational improvement at lower cost. Potentially, this could increase productivity, improve quality, reduce costs, improve speed, create a safer environment for patients and staff and exceed customer expectations.

Figure 2 – Lean vs Six Sigma

How are Lean and Six Sigma similar?

Lean and Six Sigma are both customer-focused process improvement methodologies. They both follow the traditional quality improvement steps:

- Identify the project

- Nominate projects

- Evaluate projects

- Select a project

- Ask: Is it quality improvement?

- Establish the project

- Prepare a statement of goals

- Select a team

- Verify the statement of goals

- Diagnose the cause

- Analyze symptoms

- Confirm or modify statement of goals

- Formulate theories

- Test theories

- Identify root cause(s)

- Remedy the cause

- Evaluate alternatives

- Design remedies

- Design controls

- Design for culture

- Prove effectiveness

- Implement

- Hold the gains

- Design for effective quality controls

- Foolproof the remedy

- Audit the controls

- Replicate results and nominate new projects

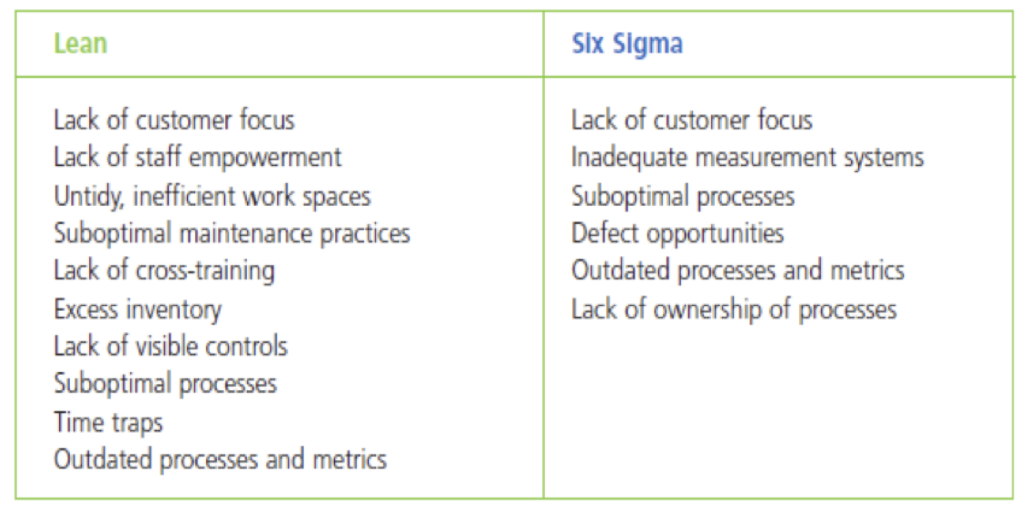

Table 2 – Comparison of common problems identified by Lean and Six Sigma

How are Lean and Six Sigma different?

At one level, both Lean and Six Sigma are improvement methodologies. However, as you investigate further, the contrasting aspects of the two approaches becomes apparent. Lean is often seen as an efficiency approach that focuses on improving flow in the value stream and eliminating waste. It is more than this however… Lean is a philosophy, not simply an exercise in eliminating waste. Lean is much more than episodic Kaizen (rapid improvement) events; it is a continuous improvement approach. It asks the question, “Why does this process exist at all? What is the value and the value stream?” Six Sigma, by contrast, is often considered an effectiveness approach that focuses on the elimination of defects and reducing variation. It is seen as working best in an environment where there is variation. Six Sigma is about the “How can we improve this process?” and not the “Why does it exist at all? Six Sigma is not just statistics, in its best incarnation; one integrates experience, historical, prospective, and data to make decisions. Six Sigma projects can last from hours to months, the methodology is not designed to tackle every problem in a set amount of time, but it is designed so projects do not take any longer than necessary.

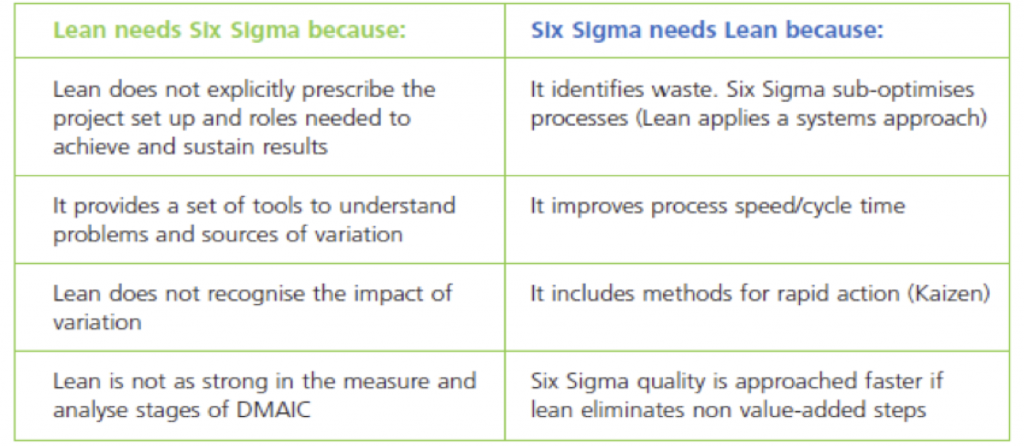

Table 3 – Why Lean and Six Sigma need each other

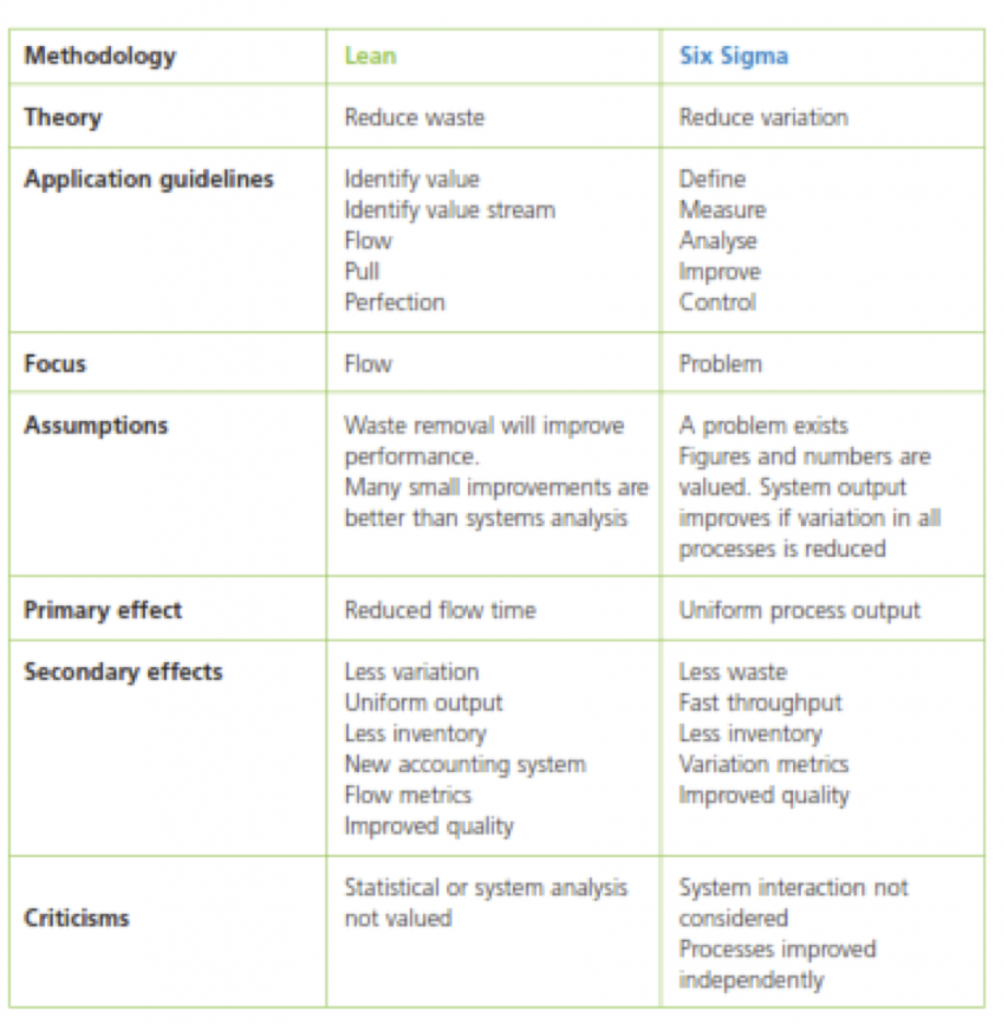

Nave (2002) has summarized the differences between the two approaches. See Table 4 – Six Sigma and Lean. Nave argues that it is the organizational culture that makes the difference about which method is appropriate and that many methods appear similar when their secondary effects are considered.

Table 4 – Six Sigma and Lean

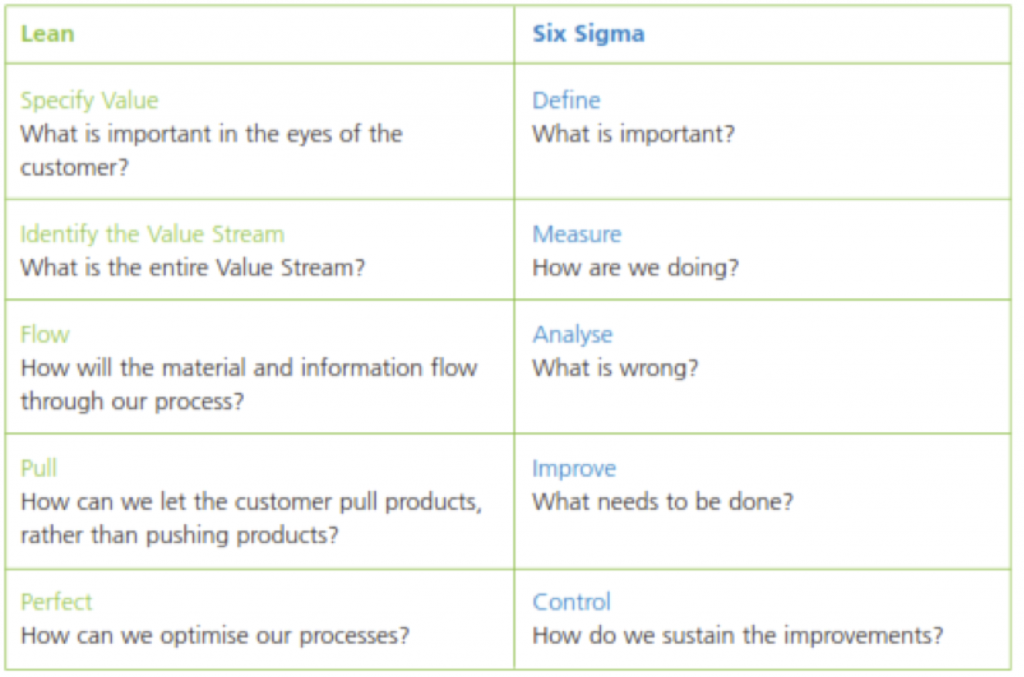

The two methodologies follow different approaches. See Table 5.

Table 5 - A contrast of the commonly taught approaches to Lean and Six Sigma

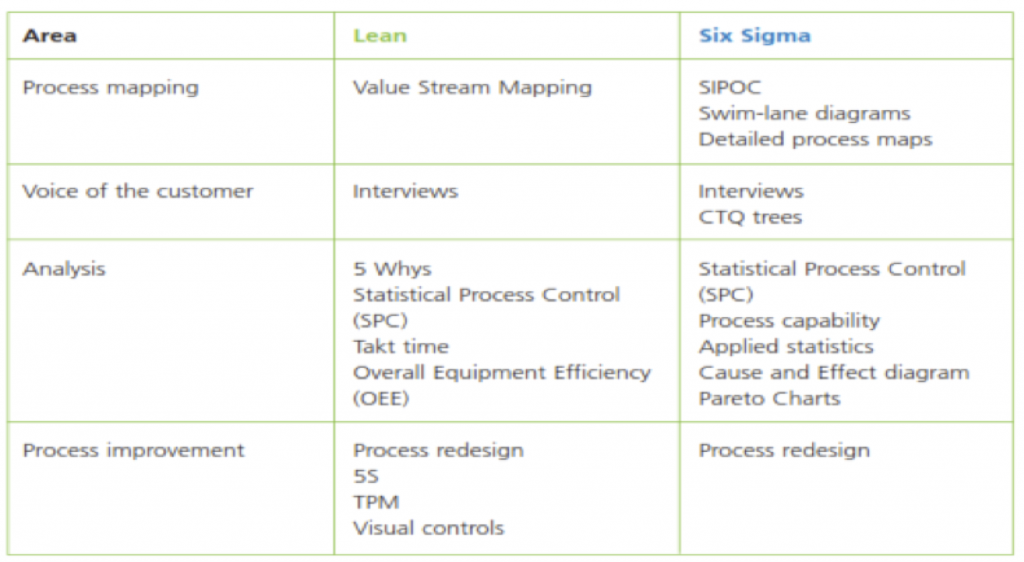

While the intent of the two approaches is similar, the tools they use are different, as below:

Table 6 - A comparison of the commonly used tools of Lean and Six Sigma

How are we integrating Lean and Six Sigma?

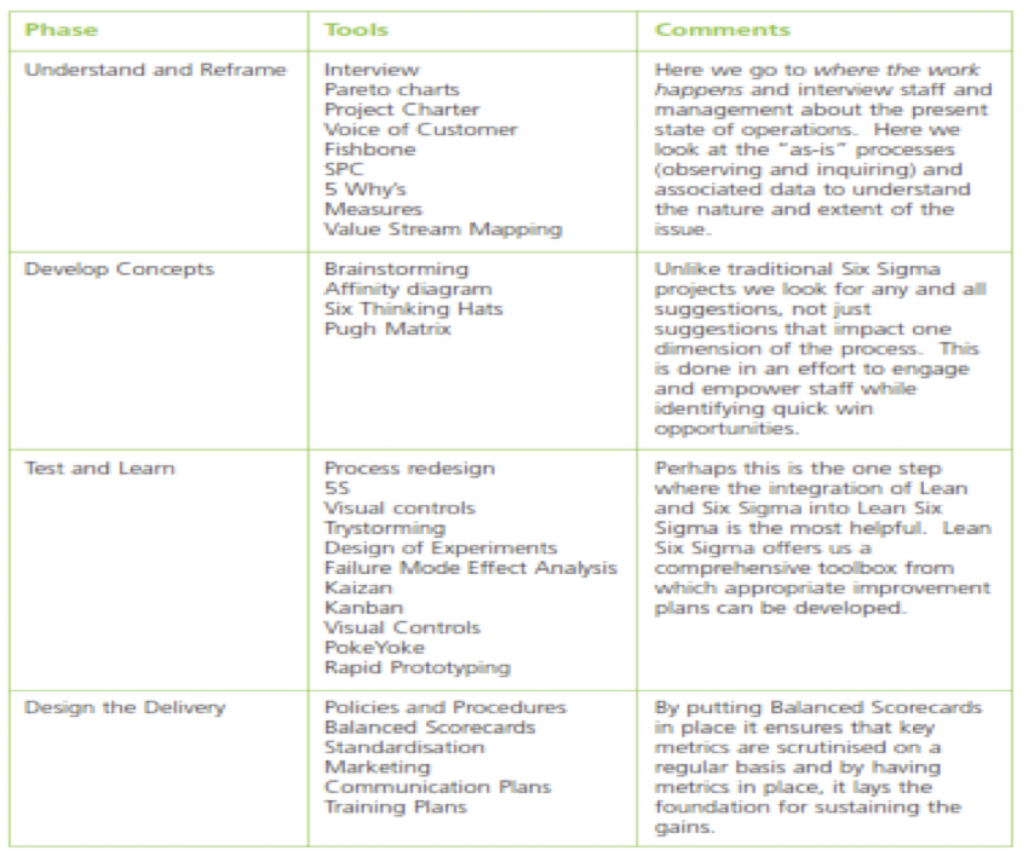

We have found that using around 20% of the tools achieves 80% of the benefits. We do this by focusing on the vital few things that will save time and maximize the impact gained. In healthcare settings, we have started to identify what value our customers are demanding and we have identified core value streams in healthcare. We have used Six Sigma tools to help us understand and reduce variation. The Lean Six Sigma approach we are starting to develop is:

- Understand and Reframe.

- Develop Concepts.

- Test and Learn.

- Design the Delivery.

Table 7 - Tools of Lean Six Sigma

Sample Healthcare Experiences

Lean techniques, such as value stream mapping, have been used across various European healthcare systems particularly in the UK and Germany since the mid 1990’s and largely through episodic Kaizen events or by combining Lean tools with other improvement approaches. Increasingly in the UK, Lean is being utilized on a much more systematic basis, with a number of healthcare organizations stepping up to focus on organization-wide value systems to achieve their strategic goals. The starting point for the Lean Six Sigma initiative was a Six Sigma pilot program, which was set up on a countrywide basis. The program was externally evaluated. This demonstrated that Six Sigma has both strengths and limitations as an improvement methodology for healthcare. One of the key issues has been whether the basic premise of Six Sigma works in healthcare. That is, to what extent can it take an existing clinical process, apply a variety of analytical, measurement and improvement techniques and improve its sigma score to a level where the process is virtually “defect free”? Participating groups identified the baseline sigma scores for projects on a range of clinical processes across the whole country. The mean baseline sigma score of the projects was 2.0 and the median sigma score was 1.9. This means that the clinical processes were defective more than 30% of the time. The lowest sigma score was 0.4, which meant that the process was defective 86% of the time. The outcomes concluded that this range of baseline sigma scores challenges the Six Sigma proposition that can take an existing process and improve it to make it defect free. The hypothesis, based on these and other Six Sigma projects in healthcare, is that many clinical processes are intrinsically ineffective. The latest study in US healthcare concluded that the “defect rate” in the technical quality of US healthcare is approximately 45%. As such, such findings concluded that it is unlikely that we can systematically improve clinical processes to get a higher sigma score. We need to redesign the basic process first. This experience was a main decision driver to combine Six Sigma with Lean production methods. If we can use Lean methods to identify value streams at a macro level, we increase the potential to design better basic processes that are more likely to benefit from Six Sigma. It is too early to synthesize the data on the outcomes of the Six Sigma projects. However, results that have come out from both UK and US hospitals so far indicate that the innovation teams within these facilities have had success in improving sigma scores by one or two, but nowhere near a “defect free” level of performance. Lean Six Sigma gives us the opportunity to get the basic processes right (through Lean) then take the variation out of the process (Six Sigma).

What are the lessons learned so far?

With extensive process re-engineering taking place across many healthcare organizations all trying a myriad of approaches and methodologies to gain improved efficiencies across the patient care spectrum; the following 10 leads can be summarized from their various journeys:

- Lean and Six Sigma are complementary not competing.

- Start with goals and strategic intent – the quest for results should determine the improvement approach, not the other way round.

- Understand where Lean Six Sigma strategy is appropriate and where it is not.

- Test the approach.

- Focus on results.

- Engage staff and change agents.

- Senior Leadership must engage and actively participate.

- Resources are required to start improvement efforts.

- Use metrics to change behavior for desired results.

- Educate, actively listen and encourage continuous improvement.

While Lean and Six Sigma were developed separately, they have similar goals and approaches. The approaches complement each other. Lean Six Sigma is a strategic approach to change. It works best when it is used as a mechanism for achieving strategic improvement goals. Value streams and value systems transcend existing organizational and departmental boundaries. The tools of Lean Six Sigma can be utilized for departmental specific improvement projects but the biggest gains can be made at an organizational or system-wide level. Never brand an improvement initiative by its methodology. Ambitions to be a “Lean Six Sigma Hospital” will not be achieved. Methods and strategies need to be behind the scenes of the goal of better patient care. Focus on results. Improvement methodologies lose their credibility if they take too long to produce results or if they are too difficult to implement. Lean Six Sigma allows us to get results quickly and to tackle difficult systemic issues as well. Link Lean and Six Sigma approaches with other tools for change and engage the staff and promote an environment of change champions that can propagate and sustain.. The CEO is a key success factor – as no change process will work without active endorsement from senior sponsorship, particularly clinical leaders. Finally; this is a continuous approach, we need to educate, listen and create an environment receptive to continuous improvement.

Conclusion

Lean Six Sigma combines two approaches that have synergy…. Both approaches require a process focus, and both include customer drivers, either to define what needs to be improved (Six Sigma) or to define value (which then drive process improvement). Six Sigma focuses primarily on reducing variation, whilst Lean focuses on improving flow in the value stream and eliminating waste, although both may have similar secondary effects. An effective combination of both approaches includes the value-maximizing philosophy of Lean, underpinned by data-driven methods in decision making (from Six Sigma) focused on the customer (from Lean). All incentives and measures are reviewed (using Lean) to ensure global optimization and minimization of variation (from Six Sigma) would be a part of this. The full benefits of Lean Six Sigma will only be realized when applied at both the strategic and operational levels, with universal application only at the strategic level. Application at the operational level results only in cost reduction, whereas application at the strategic level results in wider benefits for the organization. Both applications result in substantial benefits to patient care and overall experience. Leading hospitals are finding Lean Six Sigma as a sustainable and substantial improvement methodology that incorporates the best of Lean and the best of Six Sigma. It is very rare that two approaches to enhancing value, eliminating waste and reduce variation can be used in a complementary rather than in a competing way. See Figure 3. A pragmatic approach is required; use Lean and Six Sigma where necessary, or use Lean where Lean is necessary or Six Sigma where Six Sigma is necessary. Combining common sense (Lean) and common science (Six Sigma) offers the potential to achieve uncommon

Figure 3 - The relative strengths of the two approaches

Attend a 5-Day workshop with Mohammed Al Ayoubi in Dubai:

Transforming the Patient Experience

For more information, contact PLUS Specialty Training

+971 (0) 4 556 7171 [email protected] www.meirc.com/plus

Related Blogs

Implementing AI into your organization. Where do you begin?

Starting with AI in Your Organization: Building the First Capabilities Artificial Intelligence (AI) is transforming the business landscape, offering unprecedented opportunities for innovation, efficiency,...

Healthier Financials from the Patient Experience

Performance on patient experience scores can impact the cash flow and operating profit margins of hospitals, which may mean organizations have to align quality metrics and leadership to influence patients’ percepti...

Healthcare Leadership Development

Healthcare is one of the largest industries in the world and those employed within it are responsible for ensuring that everyone has access to healthcare in a timely, cost-effective and seamless manner....

Turning the Credit and Collections Department into a Profit Earning Function

Below is a real-life case study by Jon Ray MICM. A few years ago, I was doing some consultancy work for one of the big European banks. This institution had some i...